Railway

Safely on track – with TÜV AUSTRIA Group. Contact us at rail@tuvaustria.com

Region Asia/Africa: asiaafrica@tuvaustria.com

Region Austria:

austria@tuvaustria.com

Region Europe:

europe@tuvaustria.com

The TÜV AUSTRIA railway solution portfolio includes the following:

Certification | Services | Testing & Inspection | R I S E ® by TÜV AUSTRIA | Mechanical and Material testing | Mechanical testing laboratory and workshop | Railway fixed equipment testing and approval services | Advanced metallographic laboratory | Inspection services, damage analysis and non-destructive testing | Contact wire testing capabilities | EMC and EMI services | Environmental test chamber

Safely on track – with TÜV AUSTRIA Group

Be on track with the independent TÜV AUSTRIA, a leading international testing, inspection, certification and education services provider, and your accredited and notified railway systems expert.

Before you embark on your TÜV AUSTRIA journey to safety and security, here are a few of the stops you will be visiting: as an EN ISO/IEC accredited testing laboratory (ISO/IEC 17025 T, ISO/IEC 17020, ISO/IEC 17065), TÜV AUSTRIA covers infrastructure components, vehicle components, overhead lines, bogie tests, damping systems and sleepers.

TÜV AUSTRIA is also certified in accordance with the European standard EN 13816 for service quality in public passenger transport. TÜV AUSTRIA is your Conformity Assessment Body (NoBo, DeBo, AsBo and OC-ECM), your evaluation (Independent Safety Assessment) and inspection (systems, products, components, etc.) body.

Founded in 1872, TÜV AUSTRIA today blends digitalization processes with engineering solutions, introducing RISE to the railway sector for remotely monitored infrastructural integrity.

Now all aboard the “TÜV AUSTRIA 1872” to railway safety and security.

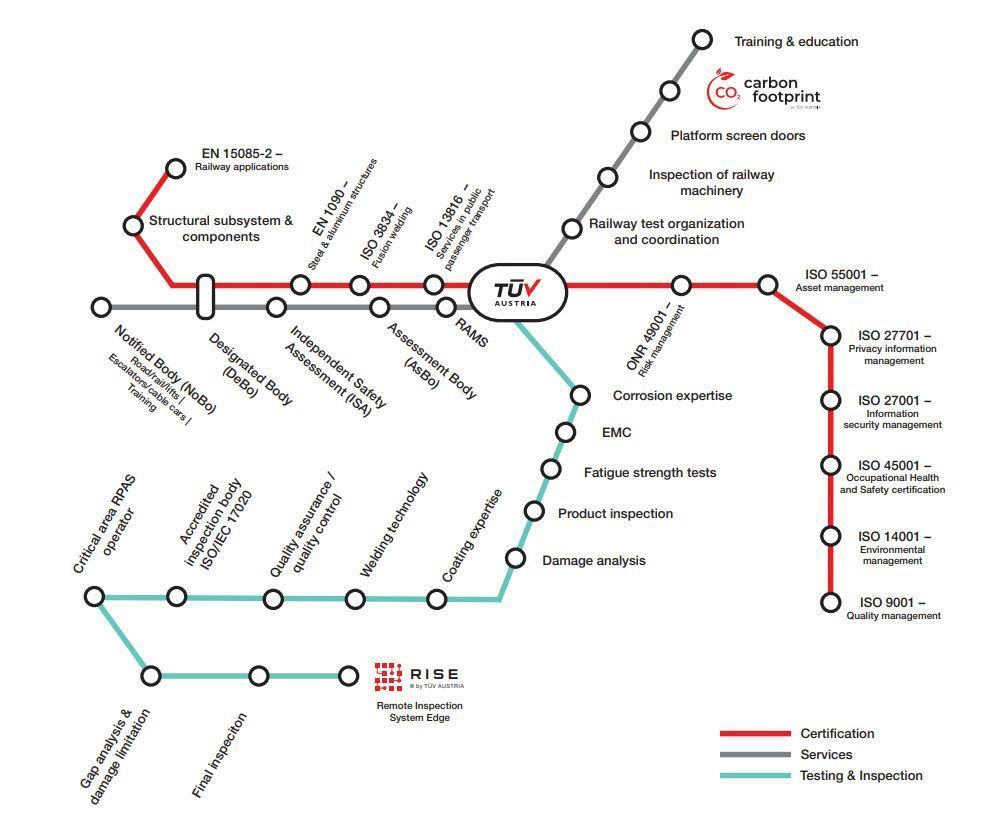

Certification

- ISO 9001 – Quality management

- ISO 14001 – Environmental management

- ISO 45001 – Occupational Health and Safety certification

- ISO 27001 – Information security management

- ISO 27701 – Privacy information management

- ISO 55001 – Asset management

- ONR 49001 – Risk management

- ISO 13816 – Services in public passenger transport

- ISO 3834 – Quality Requirement for Welding

- EN 1090 – Steel & aluminum structures

- Structural subsystem & components

- EN 15085-2 – Railway welding applications

Services

- Notified body / OIF

- Designated body

- Independent Safety Assessment (ISA)

- Assessment body (ASBO)

- RAMS

- Railway test organization and coordination

- Inspection of railway machinery

- Platform screen doors

- Carbon Footprint by tami

- Training & education

Testing & Inspection

- Corrosion expertise

- EMC

- Fatigue strength tests

- Product inspection

- Damage analysis

- Coating expertise

- Welding technology

- Quality assurance / Quality control

- Accredited inspection body ISO/IEC 17020

- Critical area RPAS operator

- Gap analysis & damage limitation

- Final inspection

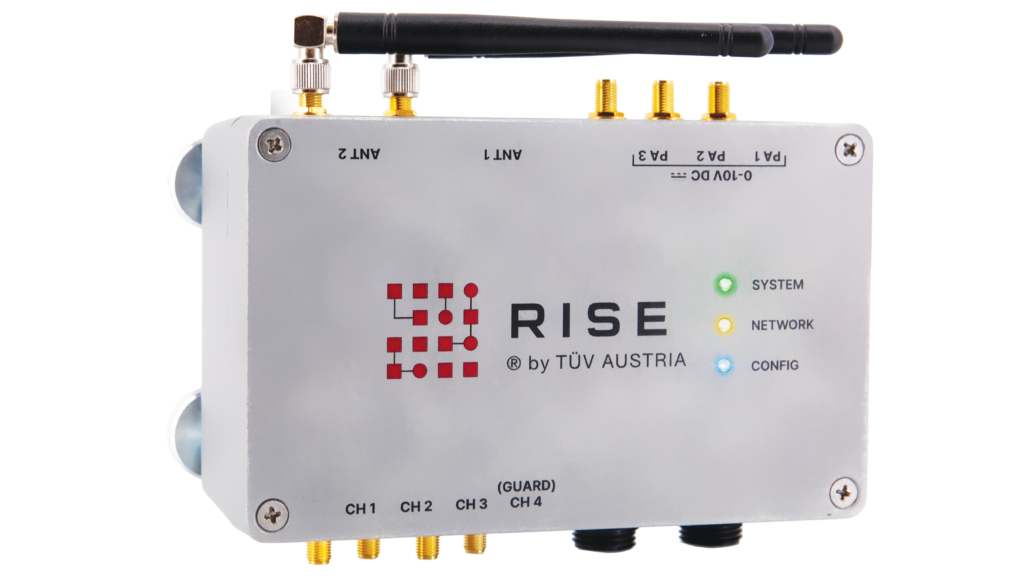

- RISE – Remote Inspection System Edge

Structural health monitoring as a service

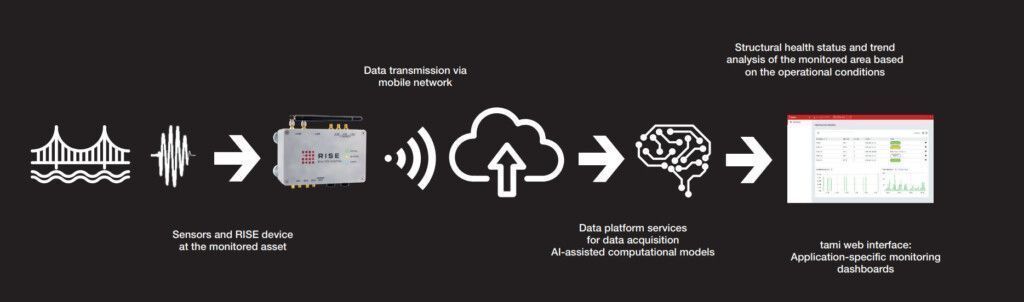

RISE is a unique system solution for structural

health monitoring of hot spots / fatigue cracks. It

is a stand-alone system solution for structural health

monitoring based on acoustic emission technology.

The system is specifically designed for monitoring

due to its compact design, low power consumption

and simple installation.

This service includes the initial connection of the

RISE system to the Tami web platform for each

deployment, regular monitoring of results by TÜV

AUSTRIA experts – particularly during the phases

between calibration and the traffic light phases – the

evaluation of special events and the preparation of

detailed reports.

For detailed information visit rise.tuvaustria.com

TÜV AUSTRIA offers independent testing, inspection and certification services as an accredited body to the rail industry (EN ISO/IEC 17020, 17025, 17065).

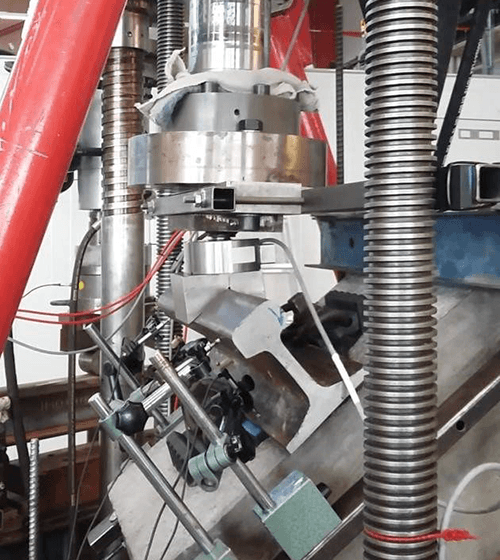

We test infrastructure components, rolling stock components and overhead lines. Our services include bogie testing, damping systems, ties, rail fastening systems, wheel and machine components, overhead lines and the connections and guy wires they require, as well as rails and rail joints.

We also perform mechanical testing and characterisation of components and materials. We test under realistic conditions and have appropriate facilities, even for complex structures and large components. Our range of state-of-the-art metallographic methods completes our mechanical testing services.

We perform EMC and EMI measurements in the lab and on-site.

For detailed information visit en.tuvaustria.com/mechanical-material/

Mechanical testing laboratory and workshop

- Material and component testing, static and dynamic

- Fatigue testing up to full-scale components

- Multi-axial test field 13×20 m

- Tensile and compression testing up to 45 MN and 20 m clamping length

- Torsion testing Fracture mechanic testing

- Chemical analysis Full metallographic analysis (REM/EDX)

- Corrosion testing

- Volatile Hydrogen measurement

- Climate chambers (10 m3, -40 °C to +90 °C, 95 % humidity)

- In-service measurement of force, displacement, acceleration, strain gauge 250+ channels

- Non-contact 3D strain measurement ARAMIS

- Tomography iCT, 225/450kV, voxel size 2 micron, specimen 200 kg 1100 mm x 1675 mm, in-situ load 5 kN 250 °C

- Damage analysis

Railway fixed equipment testing and approval services

TÜV AUSTRIA performs full approval testing for flash-butt or aluminothermic welding processes (EN 14587, EN 14730), rail fastening systems (EN 13481, EN 13146), sleepers (EN 13230, EN 16431). We perform fatigue and strength testing of wheelsets, bogies, frames according to EN 13749, UIC 515-4, UIC 615-4.

We also test any component or system, including insulated rail joints and clamping elements in accordance with technical delivery conditions.

Many customers ask for special tests during their R&D process, such as testing under special environmental conditions (from -70°C to high temperatures), unusual loads or measurement conditions and fatigue testing over long durations and corrosion tests in our salt spray chamber.

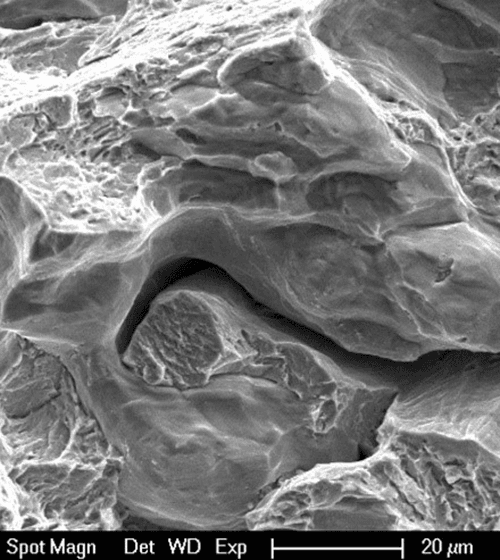

Advanced metallographic laboratory

TÜV AUSTRIA operates a state-of-the-art metallographic laboratory. In collaboration with the Vienna University of Technology, it offers light microscopy and scanning electron microscopy (SEM/EDX) capabilities, as well as microhardness testing and full chemical analysis.

Inspection services, damage analysis and non-destructive testing

TÜV AUSTRIA experts perform inspections on railway components, including welding joints for QA/QC, factory acceptance test or in case of damage assessments for all kinds of railway infrastructure components and systems. We offer the whole service range, offering standard and advanced non-destructive testing (NDT) methods.

Contact wire testing capabilities

TÜV AUSTRIA performs approval tests and product certifications according to customer specifications. This includes clamping lengths up to 50m, heating up to 220°C, measuring of thermal expansion coefficients and transition points, vibration tests and damage analyses of cables and wires in accordance with German standard VDI 3822.

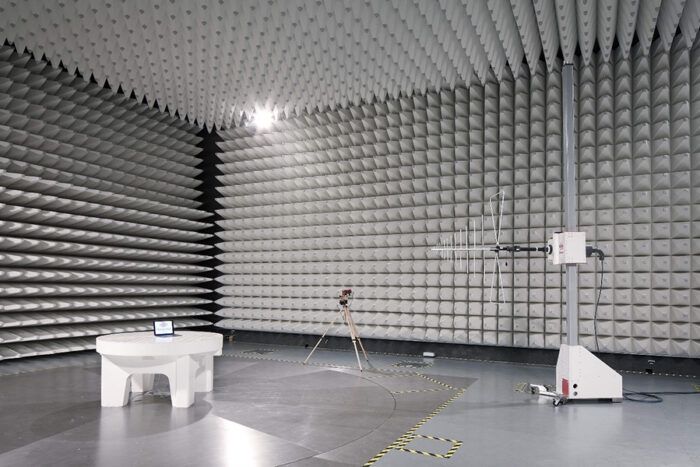

EMC and EMI services

- EMC and EMI services (EMC-Directive 2014/30/EC, RE-Directive 2014/53/EC, EN 50121 and IEC 62236).

- Semi-Anechoic Test chambers up to 13x10x6m/Quiet Zone Ø2m@3m and Ø6m@5m Measuring Distance/max 8t/Door 3mx3m

- Power supplies

- Mains simulation: 400 kVA | max. 1000 VAC (L-L) |16 – 800 Hz

- Battery simulation: 378 kW | max. 1500 VDC | max. 756 ADC Notified Body for EMC (EU-Directive 2014/30/EC) and RED (EU-Directive 2014/53/EC)

- Telecommunication Certification Body (TCB) – Federal Communications Commission (FCC) USA

- Conformity assessment body (CAB) – Innovation, Science and Economic Development (ISED) Canada

- Accredited test Lab for more than 500 EMC (EN, IEC, CISPR, ETSI, etc.) Standards, Radio Standards and Product Standards e.g.:

- RTCA DO-160G (Environmental Conditions and Test Procedures for Airborne Equipment)

- UN Vehicle Regulations – Regulation No. 10 – Rev.5 (Uniform provisions concerning the approval of vehicles with regard to electromagnetic compatibility)

- MIL-STD-461F (requirements for the control of electromagnetic interference characteristics of subsystems and equipment)

Coming soon:

Drive-in environmental test chamber

- -40 °C to +75 °C | Humidity up to 95 % | Drive-In size

- Energy efficiency test bench incl. acoustic measuring equipment

- Power supplies & communication available

Safely on track with TÜV AUSTRIA

Contact us at rail@tuvaustria.com

Region Asia/Africa: asiaafrica@tuvaustria.com

Region Austria:

austria@tuvaustria.com

Region Europe:

europe@tuvaustria.com