With the increasing shift from pure natural gas to natural gas-hydrogen mixtures and even 100% hydrogen gas flows, there is a growing need to check existing gas pipelines and networks for their adaptability and resistance to hydrogen molecules. As Austria’s leading testing, inspection and certification service provider, TÜV AUSTRIA is on hand to provide advice and support, with a focus on safety-relevant processes.

From data analysis to evaluation

TÜV AUSTRIA recently provided support in the evaluation of an existing natural gas pipeline of Wiener Netze for the transportation of up to 100% hydrogen. The focus was on researching standards and examining the state of the art. Specifically, the use of materials and welding seams for hydrogen transportation was examined. The special challenge in this project was that essential data had to be extracted from documents that were more than 30 years old using data mining. For this purpose, a separate database was created with all the necessary data for the relevant sections (Simmering to Donaustadt power plant and Donaustadt power plant to Aderklaa). This included the type of various components, their material, age, diameter, wall thickness, heat treatment condition and fracture toughness value. This was followed by comprehensive analysis and evaluation procedures to assess the existing natural gas pipeline and to determine the safety factor of the pipe string and calculate the maximum allowable operating pressure (MOP) based on the available information.

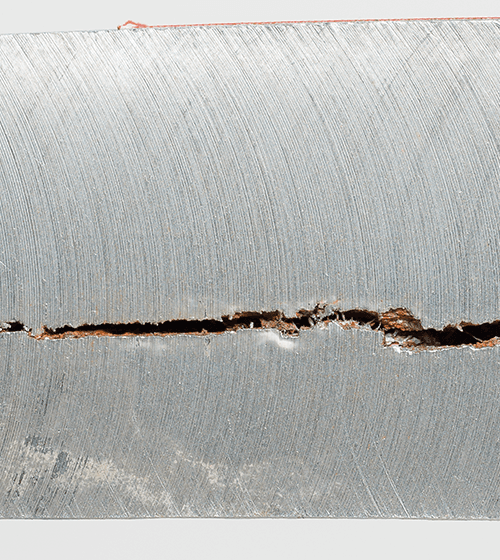

The detail is in the molecule

As hydrogen (H2) is a much smaller molecule than natural gas (CH4), it can penetrate the material more easily and also penetrate seals more easily, for example. In addition, hydrogen can cause limited material defects such as (hairline) cracks and small corrosion spots to grow. The strength properties of materials, such as hardness, tensile strength and impact strength, are impaired and lead to hydrogen embrittlement. Therefore, a thorough investigation and evaluation must be carried out to assess whether existing networks are suitable for the transportation of hydrogen.

IEC 62443 standard

Successful certification

of the liquid gas terminal from EGEGAZ

TÜV TRUST IT TÜV AUSTRIA GMBH successfully certifies EGEGAZ’s liquefied natural gas (LNG) terminal according to IEC 62443 standard 2-1, 2-4, 3-2 and 3-3.

TÜV AUSTRIA wins Digital Innovation Award

RISE by TÜV AUSTRIA wins

BEMAS Digital Innovation Award 2025

RISE by TÜV AUSTRIA, the in-House developed stand-alone solution for online monitoring of infrastructure components, has been awarded the BEMAS Digital Innovation Award at Maintenance Antwerp 2025. Wir congratulate our RISE by TÜV AUSTRIA research & development team.

Artificial Intelligence (AI) – Guideline

Best Practice Guideline

Technical Documentation of AI Systems

Safe and comprehensible: In cooperation with the Austrian Regulatory Authority for Broadcasting and Telecommunications (RTR), TÜV AUSTRIA has developed a best practice guide for the technical documentation of AI systems.

TÜV AUSTRIA Iberia

Inauguration of the new Jecma laboratories

New facilities in Paterna – Valencia

Jecma, part of TÜV AUSTRIA Iberia, continues its path of innovation and growth with the inauguration of its new facilities in Paterna – Valencia. This new location reflects the strong development of the company and TÜV AUSTRIA’s commitment to new business areas, consolidating our presence in the sector.

Middle East & Africa

Conformity Certification

of Product Exports

TÜV AUSTRIA hosted a seminar on “Product Export Conformity Certification for the Middle East and Africa” in Yiwu together with Embassy of the Republic of Iraq in China, attracting clients from various industries.

Global Trade Conformity

TÜV AUSTRIA China

builds Trust for China-Iraq Trade

Ivan Huang, Managing Director of TÜV AUSTRIA China, attended the Centenary of Iraqi Diplomacy and the 7th Anniversary of the Victory over Terrorism. TÜV AUSTRIA’s participation strengthened its cooperation with the Iraqi government and the Embassy of the Republic of Iraq in China, further enhancing China-Iraq economic and trade relations.