Solution: Filling station (liquid gas, LPG)

Solution: Filling station (liquid gas, LPG)

Inspection types

Inspection types

In the following, only tests are described which, due to the high hazard classification of the pressure equipment, are to be monitored by an inspection body in accordance with ISO 17020.

- First operational inspection and preparation of an assembly assessment in accordance with §7 Para.5 DGÜW-V: Verification of lawful placing on the market; assessment of the assembly; verification of the suitability of the components used; assessment of the installation; inspection of the cathodic corrosion protection.

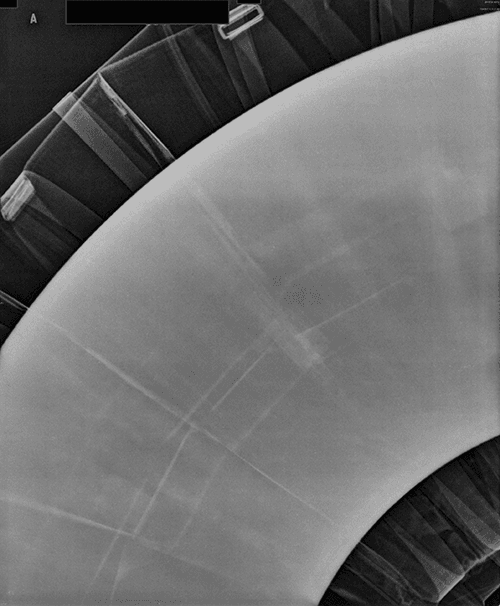

- Periodic inspection of the storage tank – link: Inspection body/ Liquefied gas/container Types of test

- Recurring inspection of pipelines with a high hazard potential is carried out in the form of a leak test with 1.1 times the operating pressure and an external inspection.

- Inspection of the cathodic corrosion protection, consisting of the determination of the protective current and potential measurements with the aid of a reference electrode.

Accreditation

Filling station (liquid gas, LPG)

Liquefied petroleum gas (LPG) filling stations usually consist of a storage tank, a delivery system, pipelines and one or more dispensers including all necessary measuring, control and regulating equipment. The entire system is to be treated as an assembly.