Solution: ICT Industrial Computed Tomography

Solution: ICT Industrial Computed Tomography

ICT - Industrial Computed Tomography

In which region do you need this solution?

ICT - Industrial Computed Tomography

ICT – Industrial Computed Tomography

X-rays to display external geometries in three dimensions, internal structures and

defects of objects.

With the help of industrial computed tomography (CT), X-rays can be used not only to display external geometries in three dimensions, but also all internal structures and defects of objects.

It is also possible to track and analyse the damage behaviour of components by means of a testing machine through tension/compression in real time – this is also possible in a temperature interval. This procedure is called

„in-situ CT“ (or 4D CT).

Differences to medical computed

tomography

In industrial CT, the object to be examined

rotates through 360°.

X-ray voltage and duty cycle:

- Medicine: Maximum 120 kV for a few seconds

- Industry: up to 600 kV for a few hours or days

ICT Computed Tomography by TÜV AUSTRIA

- largest and most powerful CT in Austria

- Unique test chamber for tensile and compression tests in Austria

- Detail detectability of a few microns 2 X-ray tubes with X-ray voltages of 300 kV and 450 kV

- Maximum possible component dimensions: Ø 1100 mm x H 1675 mm

- Maximum component weight: 200 kg

- Different detectors for component digitisation

- Metals, non-ferrous metals, plastics, composites, technical ceramics and building materials such as wwood, stone or concrete; textiles

ICT Industrial Computed Tomography: Areas of Application

Destructive testing and in-situ CT

- Tracking crack initiation and propagation

- Tensile/compression tests with defined temperature

Non-destructive testing

- Identification and colour representation of pores, cracks, blowholes, and inclusions

- Location, overall proportion, and manifestations of inhomogeneities

Weld seam inspection

- Assessment of welds regarding welding defects such as pores, binding defects, inclusions, etc.

Damage analysis

- Determination of the actual state as a 3D model

- Detection of defects

- Representation of damage areas

Assembly control

- Control of installed components

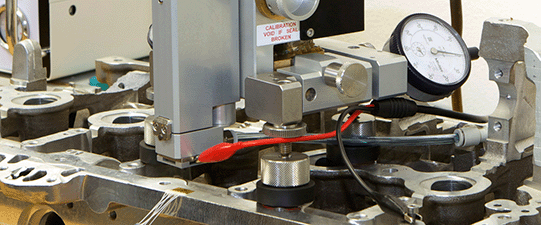

Coordinate measuring technology

- Measurement and representation in 2D and 3D

Segmentation of multi-material constructions

- Separation of different materials

Nominal/Actual comparison

- Determine the differences to technical drawings

3D wall thickness measurement

- Analysis and colour-coded representation

Reverse engineering

- Conversion of a CT scan into a CAD model

Manufacturing geometry correction

- Corrections of tools or moulds

- Mesh compensation to eliminate deviations of the actual geometry of additively manufactured components

Simulation

- Component digitisation for FEM analyses

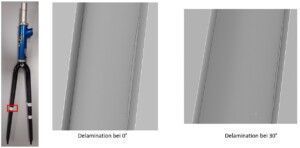

CFRP bicycles testing

We offer high-precision X-ray inspections for CFRP bicycles using industrial computed tomography (CT). This technology enables a detailed analysis of the internal structure without damaging the material.

Detect microcracks and defects at an early stage and ensure the quality and safety of your bicycles.

Rely on our expertise for reliable testing of your carbon fiber components.

CFRP frame

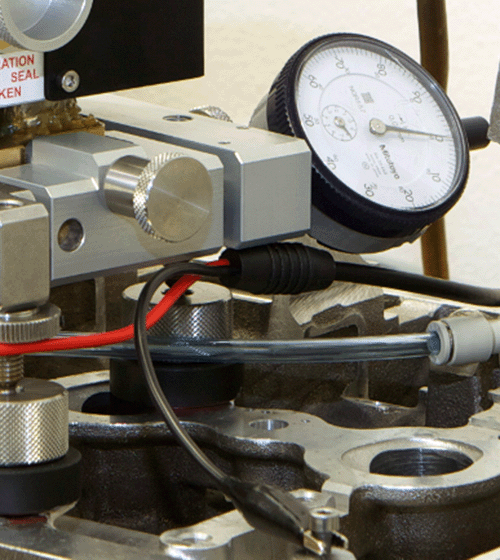

CT and Materials Testing

Industrial computed tomography is a new testing method in materials testing.

The advantage over conventional radiographic testing lies in the three-dimensional

representation and digitisation of the data. With the help of evaluation

software, a variety of analyses are possible.