Solution: Vehicle Modification Approval for passenger cars and light trucks

Solution: Vehicle Modification Approval for passenger cars and light trucks

Passenger vehicle and light truck modification approval - Legal framework conditions in road traffic for vehicle modification

Termin buchen

Passenger vehicle and light truck modification approval - Legal framework conditions in road traffic for vehicle modification

Overview

The conversion of vehicles is subject to various legal framework conditions. This page provides an overview of the legal framework conditions in road traffic. Please note that these are not legally binding.

You can access our services here:

- Passenger vehicles and light trucks

- Motorcycle

- Motor home

- Homologation

Do you need our expertise? Make an appointment online now.

Passenger vehicle and light truck modification approval - Legal framework conditions in road traffic for vehicle modification

Vehicles in general

Vehicle modification approval in Austria

Vehicle modification means the modification of components deviating from the standard condition of a vehicle, such as changes to tyre combinations, chassis, add-on parts, etc., the use of which was not provided for in the approval document (COC document, type certificate or individual approval notice) for the vehicle type. In Austria this is called “Typisierung”.

General Requirements

In principle, every modification carried out on a vehicle must be approved (= typisiert) in accordance with §33 KFG (click here). This paragraph states that the modification must not lead to a deterioration in traffic and operational safety.

This proof can be provided in various ways – either by a release from the general importer (can only be provided if this condition also existed as an optional series condition) or by an expert opinion from a test centre.

These certificates can be either parts certificates (must be supplied by the parts manufacturer with the parts) or individual certificates (if no parts certificates are available or if components affecting each other are changed [lowering and wheel/tyre combination] an overall certificate). These individual certificates are issued for exactly your vehicle with the changes made and are therefore only valid for this one vehicle!

As soon as all corresponding expert opinions are available, the changes can be entered into the approval document by the Landesregierung (click here for an overview) (i.e. the entry into the approval document is not made by TÜV AUSTRIA).

Changes without the need for approval

§22a KDV (click here) lists all changes that do not have to be approved:

- Lights and reflectors with EC approval (E approval mark).

- Additional headlamps for main beam (provided the permissible index for luminous intensity, currently 100, is not exceeded, but no more than 2 pairs)

- Daytime running lights with EC approval (E approval mark)

Trailer couplings with EC approval (E approval mark); however, a failure check for the trailer’s turn signals must be present. - Silencers with EC approval (E-approval mark)

- Frontal protection systems (bull bars) with EC approval (E-approval mark)

- Alloy wheels with EC approval (E-approval mark)

- Window tinting films with an approval mark of an EU member state; sticking them on the windscreen is not permitted (not even sun visor strips!)

Passenger vehicle and light truck modification approval - Legal framework conditions in road traffic for vehicle modification

Wheel/tyre combinations of passenger cars and light trucks

Every modified wheel and/or tyre combination (even if it is only a non-original wheel or a modified tyre dimension) must be approved (except for wheels in near-standard dimensions and ECE approval / E-mark)! For the approval of modified wheels/tyres, you must bring the following documents for the preparation of an expert opinion for your vehicle:

- Proof of strength of the installed wheels (can be provided by parts certificate, ABE or strength certificate).

- For tyre widths outside the relevant standard (ETRTO – European Tire and Rim Technical Organisation), a current release from the tyre manufacturer.

Our experts will then inspect the mounting on the vehicle, among other things:

- Wheel connection, wheel fastening – use of the correct fasteners (ball, taper or flat collar; bolt length).

- Clearance – the fully sprung vehicle must not rub against the bodywork (at least 6mm clearance).

- Wheel cover – the entire wheel/tyre combination must be covered by the wheel centre in a range of 30° before to 50° after a vertical (if this is not possible, well bonded wheel cover strips are permissible)

- Check the permissible wheel loads of the tyres and wheels (depending on the rolling circumference).

- If the rolling circumference deviates by more than ±2%, the speedometer must be checked.

- Check that the correct valves (rubber, metal screw or special valves) are used.

- Use of snow chains (usually already excluded by the wheel manufacturer)

- Check whether the track width change (<4% for off-road vehicles with ladder frames, <2% for all other vehicles) is within the permissible range.

- In the case of more severe changes, various additional tests, such as the effect of the change in the steering roll radius and driver testing in extreme cases. Note: In the case of simultaneous lowering, an overall expert opinion is usually required.

Passenger vehicle and light truck modification approval - Legal framework conditions in road traffic for vehicle modification

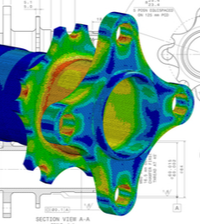

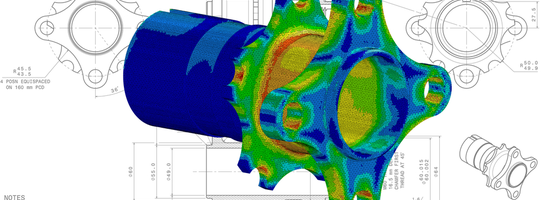

Chassis modifications of passenger cars and light trucks

Chassis modification

Any modification to the chassis, with the exception of replacing the standard shock absorbers with sports shock absorbers with the same functional dimensions, must be notified! The following points must be observed when modifying chassis or springs:

- Lowering must not result in a deterioration of traffic and operational safety (i.e. road contact with safety-relevant components must be excluded). The regulations on how this is to be assessed are decided by the VdTÜV (www.vdtuev.de) in Germany by experts in the field and are recognised as a set of rules in the German-speaking countries (thus also in Austria).

The relevant points for lowering are defined in the VdTÜV information sheet 751: Up to 06/2006, a ground clearance of 110mm at the lowest fixed point or 80mm on shape-elastic parts is considered the relevant dimension for lowering. As of 08/2008 (and later), 80mm with the vehicle loaded to the maximum permissible axle loads is the current dimension (normally corresponds to a ground clearance of 95mm when empty). The status of the expert opinion can be found in the corresponding chassis expert opinion (parts expert opinion) under point V “Test principles”. If no explicit status of the data sheet is stated there, the date of preparation of the expert opinion must be after 08/2008. - Furthermore, the vehicle must be listed in the area of application of the certificate, and attention must also be paid to the maximum permissible axle loads.

- The springs must not be subsequently modified (painted, chromed or otherwise treated).

- After lowering, the chassis geometry (wheel alignment) and the basic setting of the headlights must be checked and corrected if necessary. In modern vehicles, the basic setting of the assistance systems must also be recalibrated!

Further information on height-adjustable suspension

- In addition to conventional lowering springs, height-adjustable suspensions are also permitted. These may be designed as threaded or air suspensions.

- Especially in the case of threaded suspensions, sufficient distance to tyres and wheels and body parts (e.g. the lower spring plate to the tyre) must be ensured.

- The adjustment range of the suspension (either the distance from the spring plate to the housing bolts or the air pressure) according to the parts certificate must be observed.

- In the case of air suspensions, care must also be taken to ensure that the peripherals (especially the air reservoir and compressor) are permanently and securely installed – these must be firmly attached to the body; attachment to the boot plate alone is not sufficient. Furthermore, the chassis must move to the desired height at the latest when the driving gear is engaged, and adjustment while driving is not permitted.

Special attention must be paid to the following points for all chassis modifications

- Sufficient distance to body and chassis parts, e.g. drive shafts, wheels, tyres, frame heads, steering levers, track rods, track heads, wheel suspensions, anti-roll bars, brake lines, cables, etc.

- No additional (plugged) spring travel limiters may be used.

- The spring must be clearly guided over the entire spring travel and a play-free fit must be ensured with fully deflected axles.

- The spring must not have any contact with the bodywork during compression (especially applicable to air suspensions with double rolling lobe air springs)

Passenger vehicle and light truck modification approval - Legal framework conditions in road traffic for vehicle modification

Silencer

- In principle, a silencer with EC approval (“E-approval mark”) is exempt from registration (however, the specific vehicle with engine type and power must be listed in the area of use). However, the respective certificate must be carried in the vehicle.

- If several different silencers and/or replacement catalytic converters are combined, the operating noise must be measured because of the mutual influence. In this case, no deterioration compared to the standard condition is permissible!

- Silencers without EC-approval can only be registered under certain conditions! In this case, a parts certificate is required in which the respective guidelines for performance, exhaust and noise behaviour are checked and confirmed. The standard values may not be worsened, also the noise level (both driving noise and in the near field) may not become louder.

- Exhaust manifolds can only be registered with a parts certificate confirming a possible increase in performance as well as the exhaust and noise behaviour.

- Self-built exhaust systems or racing exhaust systems are not registrable or are only registrable with considerable (also financial) effort.

Weld-on tailpipes

- Modified tailpipes are also subject to registration.

- Tailpipes must not protrude beyond the rear contour of the vehicle.

- The tailpipe may not be modified – the standard tailpipe must continue to be routed out of the tailpipe as in the standard condition

- The replacement tailpipe (if the original one is shortened) must be welded gas-tight

Passenger vehicle and light truck modification approval - Legal framework conditions in road traffic for vehicle modification

Attachment parts

The following points must be observed when fitting add-on parts:

- Add-on parts without a vehicle-specific certificate are only permissible to a limited extent – however, it is virtually impossible to judge this permissibility in advance from photos. Therefore, our urgent advice is to check whether a parts certificate or an ABE is available before buying – a material certificate alone says nothing about the permissibility.

- There must not be any negative influences, e.g. inadmissible reduction of ground clearance, inadmissible covering of the headlights, or similar.

- Front and rear towing equipment must remain accessible and usable.

- A headlight cleaning system (if fitted) in the front bumper must not be removed.

- Attachments must be permanently and securely fitted in accordance with the manufacturer’s installation instructions; the manufacturer’s markings must not be removed during painting!

Air filter

- Replacement filter mats in the standard air filter box are generally exempt from registration.

- The registration of open sports air filters is only possible if a type-related parts certificate is available for the vehicle and if the complete exhaust system is in its original condition or in the condition described in the certificate.

- If required in the parts certificate, a noise insulation mat must be fitted to the bonnet.

Passenger vehicle and light truck modification approval - Legal framework conditions in road traffic for vehicle modification

Brakes

- Replacement brake discs with the original dimensions (also perforated and slotted brake discs) as well as steel braided brake lines are considered replacement parts and are not subject to registration. A test report and, in the case of brake lines, an installation confirmation must be carried in the vehicle!

- Changes to brake calipers or brake disc diameters are subject to registration. Important: A parts certificate for the relevant vehicle type must be available!

- Special care must be taken when using winter tyres with snow chains, as larger brake discs or calipers may mean that the standard wheel and tyre combinations can no longer be used.

- Modified brake lines are only permitted with pressed-on screw nipples; screwed nipples (as is sometimes common in motorsport) are not permitted on the road.

Passenger vehicle and light truck modification approval - Legal framework conditions in road traffic for vehicle modification

Lighting equipment

- All lights must have an E-approval mark and are exempt from registration if the installation position and orientation are not changed.

- If there is no tested reflector in the rear light unit, additional red, non-triangular reflectors with an E-approval mark must be fitted.

Conversion to xenon headlights

- A headlamp cleaning system must be fitted

- An automatic headlamp levelling system must be fitted.

The headlamp must be approved for use with xenon bulbs.

Parking light rings (so-called “Angel Eyes”)

- The retrofitting of so-called parking light rings in a headlamp unit is not possible.

- Only headlamp units in which the so-called parking light rings are present and tested (E-approval mark) may be installed.

Passenger vehicle and light truck modification approval - Legal framework conditions in road traffic for vehicle modification

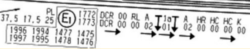

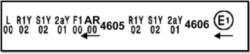

Explanation of the light codes

Symbol |

Meaning |

Vehicle class |

| 1,1a,1b | Turn signal front | car, truck |

| 11,11a,11b,11c | Turn signal front | motorcycle |

| 2a, 2b | Turn signal rear | car, truck |

| 12 | Turn signal rear | motorcycle |

| 5, 6 | Side indicators | car, truck |

| 50R | stop light, rear light, indicator | motorcycle |

| A | marker light | car, truck, trailer, motorcycle |

| AM | front outline marker light | car, truck, trailer |

| AR | reversing light | car, truck, trailer |

| B | fog light | car, truck, trailer, motorcycle |

| C,HC | low beam | car, truck, motorcycle |

| C/R,HC/R, CR, HCR | high beam | car, truck, motorcycle |

| DC | xenon low beam | car, truck, motorcycle |

| DC/R | Bi-xenon | car, truck, motorcycle |

| DR | xenon high beam | car, truck, motorcycle |

| F, F1, F2 | rear fog light | car, truck, motorcycle |

| IA, IB | reflector | car, truck, motorcycle |

| IIIA, IIIB | reflector triangular | trailer |

| K | turning light | car, truck |

| L | licence plate light | car, truck, trailer |

| LM1 | licence plate light | motorcycle |

| MA | marker light | motorcycle |

| ML | manoeuvering light | car, truck, trailer |

| MR | tail light | motorcycle |

| MS | stop light | motorcycle |

| MB, MBH, C-AS, C-BS, WC-CS, WC-DS, WC-ES, R-BS, WR-CS, WR-DS, WR-ES |

high and low beam | motorcycle |

| R, R1, R2 | rear light | car, truck |

| RL | day light | car, truck |

| RM1, RM2 | rear outline marker light | car, truck, trailer |

| S1, S2 | stop light | car, truck |

| S3, S4 | 3rd stop light | car, truck |

| SM1, SM2 | side marker light | car, truck |

| XC, XR | adaptive front light | car, truck |

| Y (afterwards) | light is part of a system | car, truck, trailer |