Solution: Pipeline (liquid gas)

Solution: Pipeline (liquid gas)

Types of testing pipelines

The following tests are carried out on liquid gas containers:

- Preliminary test (strength test): is carried out in the form of a pressure test with air or inert gas. All connections are to be visually checked for tightness under test pressure and evaluated with regard to their proper execution. Every newly manufactured, modified, extended or repaired pipe shall be subjected to a pressure test consisting of a preliminary test and a leak test.

- Leak test: is carried out in the form of a pressure test with air or inert gas. The pipeline system is tight if there is no pressure drop within 10 minutes.

- Inspection of the pressure regulators and safety devices: In addition to the visual inspection of the components, the operating pressure and the response pressures of the safety devices are checked.

| Operating pressure | Test pressure |

| up to 100 mbar |

|

| over 100 mbar | Combined pre- and leak test with at least 2 bar above the operating pressure |

Regulations and downloads

- Pressure Equipment Act, DGG BGBl. No. 161/2015

- Pressure Equipment Monitoring Ordinance, DGÜW-V BGBl. No. 165/2015

- Pressure Vessel Installation Ordinance, DBA-VO BGBl. II No. 361/1988

- Dual Pressure Equipment Ordinance, DDGV Federal Law Gazette II No. 59/2016 Link to RIS

- Liquid Gas Ordinance, FGV Federal Law Gazette II No. 446/2002

- Ordinance on the Monitoring of Liquefied Petroleum Gas Conversion Vessels

- Federal Law Gazette II No. 172/2013

- Liquid Gas Filling Station Ordinance, FGTV BGBl. II No.247/2010

- ÖVGW Guideline G2 – Technical Rules for Liquefied Petroleum Gas

- ÖVGW Guideline G7 – Liquefied petroleum gas piping systems; Piping systems for liquefied petroleum gas with operating pressures above 500 mbar up to and including 25 bar

- ÖVGW Guideline G B331 – Operation and maintenance of cathodic corrosion protection systems for underground natural gas pipelines made of steel

- Information folder “Liquid gas systems

Accreditation

Pipeline (liquid gas)

Pipeline

Liquefied gas pipelines that are not subject to the Pressure Equipment Act are dealt with here.

Accordingly, the monitoring of liquid gas pipelines is not carried out by the inspection body, but is assigned to the engineering office for mechanical engineering.

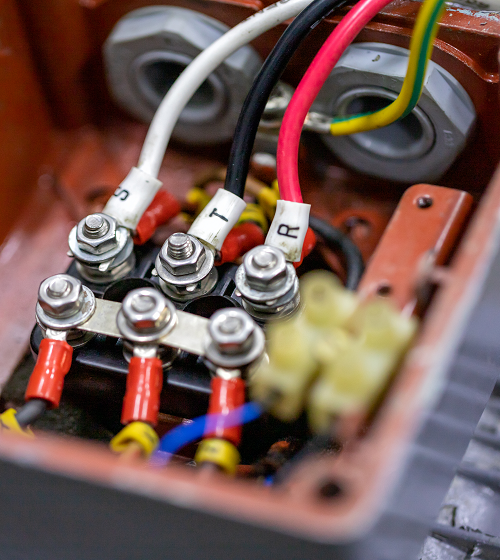

As a rule, these are medium and low-pressure pipes with operating pressures of approx. 1.5 bar (medium pressure) and 50 mbar (low pressure), which convey the gas from the storage tank to the consumers (e.g. boiler, gas cooker, …).

The pressure regulators and safety devices are also part of the pipeline system. Since pressure regulators can pose a high risk if handled improperly, they are an important part of every pipeline inspection.

TÜV AUSTRIA has already carried out more than 10,000 pipeline inspections throughout Austria in recent years.