Solution: Plant Safety: HAZOP / PAAG

Solution: Plant Safety: HAZOP / PAAG

Download: TÜV AUSTRIA - HAZOP - Analyse von prozesstechnischen Gefährdungen

TÜV AUSTRIA Fachverlag: Technische Risikoanalysen für Anlagen mit hohem Gefahrenpotenzial

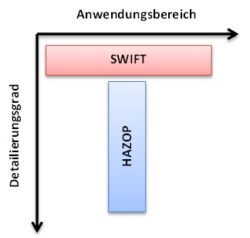

The HAZOP (HAzard and OPerability / PAAG) method has proven to be particularly efficient and flexible among the various methods for identifying sources of hazards, especially in highly complex systems.

HAZOP / PAAG: Hazard & Risk Analysis

HAZOP / PAAG describes a systematic approach to finding non-obvious sources of hazards in systems of all kinds. It is characterized by the methodical, guided brainstorming of an interdisciplinary group of experts, which requires specialist knowledge and experience in a wide variety of disciplines.

The aim is to identify a wide variety of divergences from the intended operation of a system and to discover their respective causes. The listing of possible divergences is the starting point for estimating the effects and determining appropriate countermeasures.