The TÜV AUSTRIA Technology & Innovation Center, Vienna’s most modern testing and research centre, is taking another step towards the future thanks to the opening of the new Automotive Competence Hub. The newly constructed test hall and office building complex offers all automotive tests and inspections in combination with the existing wheel and tyre test halls. Whether vehicles with conventional combustion engines, electric drives or alternative propulsion systems such as hydrogen, the perfectly networked TÜV AUSTRIA location in the south of Vienna is at the cutting edge of technology and thus the address for testing services for all aspects of motor vehicles.

From the classic car to the ultra-modern lifting platform

For car enthusiasts, the new Competence Hub represents a significant expansion of the automotive options at the TÜV AUSTRIA Technology & Innovation Center. In addition to the testing of converted or imported cars, classic cars, small trucks and motor homes, trailers and motorbikes as well as §57a inspections, state-of-the-art lifting platforms for cars and small trucks, motorbikes including assembly pits with automatic roller cover including roll-off test bench have been implemented.

The two electro-hydraulic underfloor scissor lifts for cars and small trucks with a lifting capacity of approx. 6 t and the electro-hydraulic motorbike lift with a lifting capacity of approx. 600 kg enable all offered inspections to be carried out safely and efficiently. One platform has been specially designed for electric mobility with regard to the requirements of a high-voltage workstation. The new and ultra-modern test pit for vehicle inspections is secured by an automatic roller cover made of galvanised steel with a load capacity of 10 tonnes. A 20 t hydraulic articulated play tester and a 15 t hydraulic pit jack complete the state-of-the-art equipment of our automotive competence hub.

A compact exhaust system integrated into the prefabricated assembly pit protects TÜV AUSTRIA employees and customers from vehicle exhaust fumes at the brake test stand (integrated into the prefabricated assembly pit) by means of roof ventilation. The test hall of the Automotive Competence Hub can be conveniently accessed via four electric and radio-controlled high-speed doors (3x east, 1x west). An inserted walk-through door increases energy efficiency in the cold seasons.

The driving assistance system calibration test bench as a technical highlight

Especially after structural changes to the chassis (such as lowering, raising), the calibration of assistance systems after various vehicle conversions should not be neglected, because these systems only function properly if the chassis is also correctly adjusted. For example, the function of camera-based assistance systems such as intelligent light systems depends on correct calibration. In the case of structural changes to the chassis, the adjustment of the headlights and the calibration of the assistance systems must be checked in most cases after the chassis check (measurement). TÜV AUSTRIA now offers this service thanks to the new calibration test bench and will optionally include this information in the expert opinion in the future – an additional offer for our customers.

Our customers can now comfortably follow the testing procedure on their high-quality vehicles from the modern and comfortably equipped customer waiting area through the generously designed glass pane of the connecting door between the customer waiting area and the testing hall.

Thanks to the ideally utilised spatial conditions, the state-of-the-art equipment and the optimal networking with other TÜV AUSTRIA solution offerings at the Technology & Innovation Center, e.g. the EMC hall with the possibility of performing EMC tests on vehicles and vehicle components, the Automotive Competence Hub is the perfect contact point for all testing and inspection activities on motor vehicles.

#wedo: Automotive test methods

The TÜV AUSTRIA #wedo expert videos provide a detailed insight into our wide range of solutions in the field of automotive testing procedures:

Contact:

Dipl.-HTL-Ing Christian Kubik, MBA

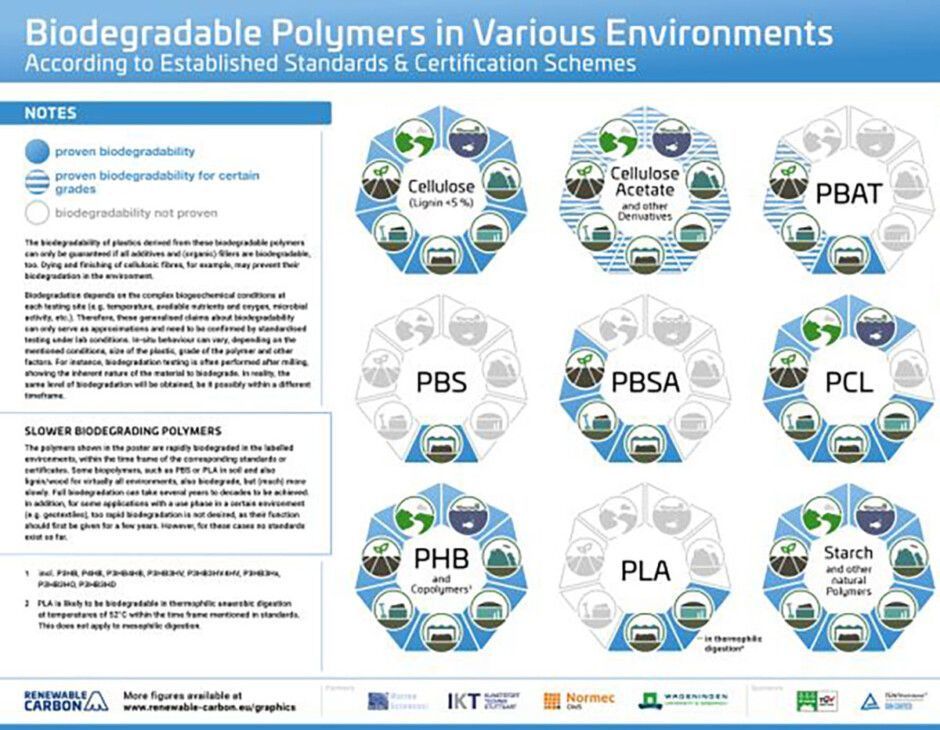

Poster published by the nova-Institut GmbH

Biodegradable Polymers in Various Environments

Collaboration of TÜV AUSTRIA Belgium

For the 3rd time, TÜV AUSTRIA Belgium collaborated in updating the “Biodegradable Polymers in Various Environments” poster, published by the nova-Institut GmbH, which lists the 9 most common biodegradable polymers and their 7 potential end of life environments.

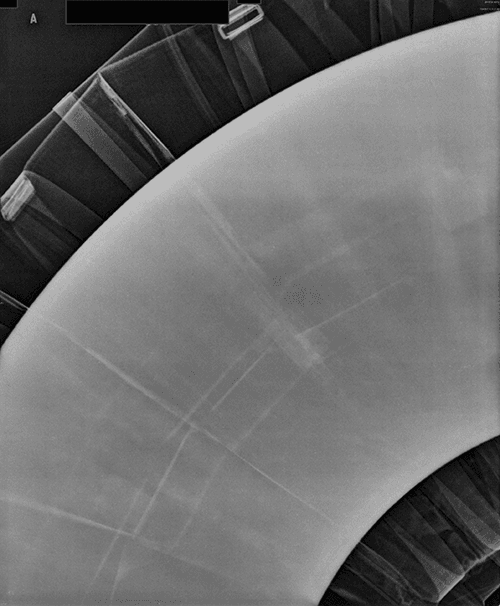

TÜV AUSTRIA acquires ISARail SpA

TUV AUSTRIA enters the

rail certification sector

ISARail SpA has been operating since 2000 as a private and independent body for safety-related issues and conformity assessments for railroad systems.

Italian training expert BRAINFORM

joins TÜV AUSTRIA Group

TÜV AUSTRIA Italia is pleased to announce a prestigious acquisition in the field of professional training: BRAINFORM Srl is now a fully-owned member of TÜV AUSTRIA Group.

EU AI Act is in force

TÜV AUSTRIA present AI position paper

TÜV AUSTRIA expressly welcomes the EU AI Act as a sensible regulatory instrument. Care must be taken to ensure that so-called low-profile certifications, which are issued exclusively on the basis paper-based tests, do not appear to be suitable for high-risk AI applications – an assessment must also include the function and performance of the system.

METALogic officially becomes

TÜV AUSTRIA Belgium

We are excited to announce that METALogic will officially become TÜV AUSTRIA Belgium by August 1, 2024. This merger represents a significant milestone, bringing together two industry leaders to deliver technical expertise and comprehensive services in the asset integrity domain.

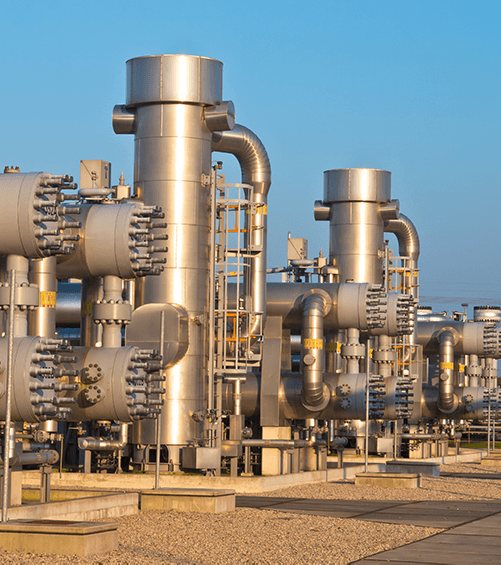

Preparations for 100 % hydrogen:

TÜV AUSTRIA evaluates existing gas pipeline